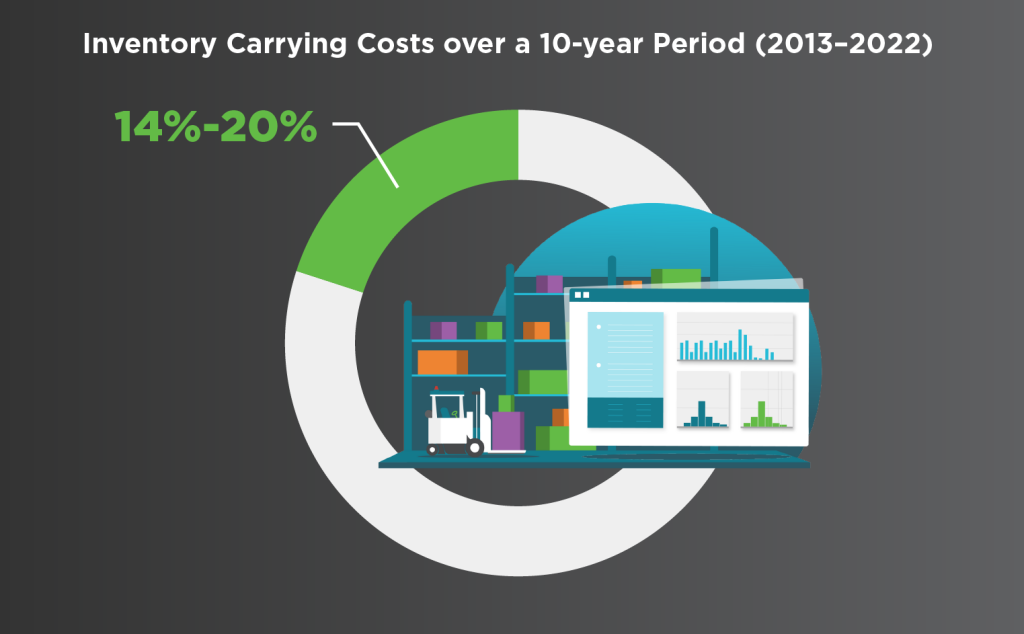

In an era where operational efficiency underpins competitive advantage, inventory management emerges as a critical focal point for cost reduction. Notably, inventory costs can account for 14% to 20% of an organization’s inventory asset value. Addressing this can unlock significant operational savings, propelling businesses toward greater profitability and efficiency.

Unpacking Carrying Costs

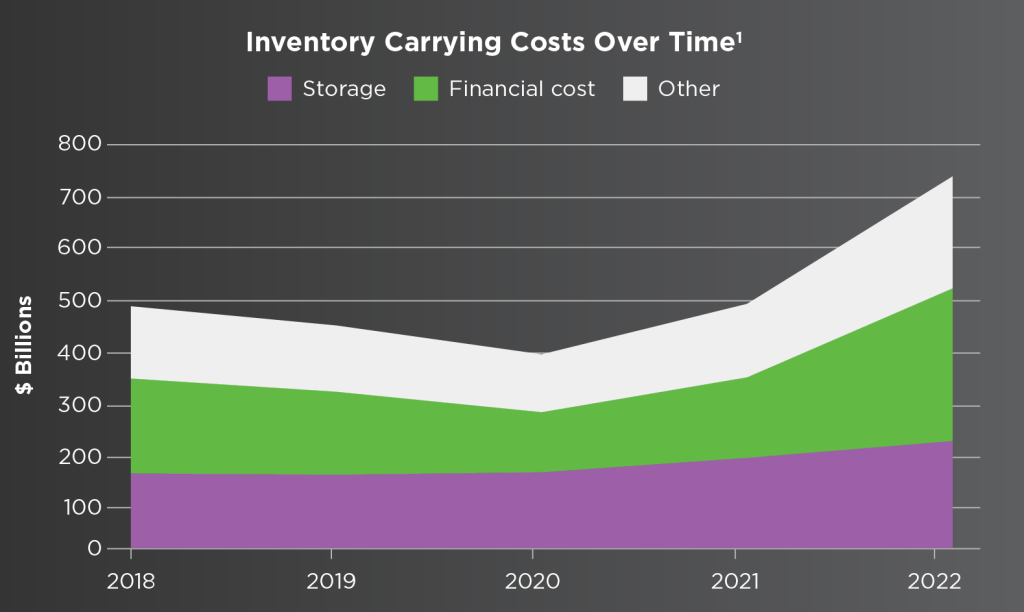

Carrying costs, the expenses incurred to hold and manage inventory, encapsulate storage, financial costs, and other costs, such as obsolescence, insurance, depreciation, and shrinkage. As these costs climb, the urgency to optimize inventory levels becomes paramount. Companies now face the dual challenge of maintaining service quality while minimizing surplus inventory to reduce these financial burdens.

The Rising Tide of Carrying Costs

Current trends reveal a concerning rise in carrying costs across industries, underscoring the importance of effective inventory management. Historical data from the Annual State of Logistics Report paints a vivid picture: inventory carrying costs over the 10-year period from 2013 through 2022 range between 14% and 20%2. Furthermore, a comprehensive 2023 analysis by American Productivity & Quality Center (APQC) across 4,268 organizations found the median inventory carrying cost to be 10%, with a striking disparity between top performers at 6% and bottom performers at 15%.3 These figures highlight a significant opportunity for optimization.

ScottMadden’s Cutting-Edge Solutions

Recognizing the imperative to curb these rising costs, ScottMadden offers tailored solutions designed to refine inventory management practices and reduce carrying costs:

Leading Practices Assessment

Our Leading Practices Assessment benchmarks an organization’s inventory management against industry standards, identifying opportunities for improvement and paving the way for enhanced operational efficiency. Explore our methodology here.

SpareLogic Service Level Setting Solution

Leveraging advanced statistical analysis and artificial intelligence (AI), SpareLogic fine-tunes service levels for spare parts, balancing cost-efficiency with service quality. This innovative approach ensures that businesses maintain optimal inventory levels, reducing unnecessary expenditure.

OptiStock Inventory Optimization Solution

OptiStock revolutionizes inventory management by employing usage patterns and service levels to establish precise reorder points. This solution, detailed further here, optimizes inventory levels, ensuring availability while minimizing carrying costs.

The escalating carrying costs present both a challenge and an opportunity for businesses across industries. Through strategic inventory management, companies can navigate these complexities, transforming a potential financial strain into a competitive edge. ScottMadden’s suite of solutions, from comprehensive assessments to advanced optimization tools, empowers businesses to achieve operational excellence, driving down costs while maintaining service quality. In the quest for efficiency, reducing inventory carrying costs is not just an option—it’s a necessity.

*Contributing author: Douglas Alvarez

1 Council for Supply Chain Management Professionals Annual State of Logistics Report (2019 – 2023)

2 Council for Supply Chain Management Professionals Annual State of Logistics Report (2023)

3 APQC. “Inventory Optimization: Show Me the Money.” APQC Resource Library, 22 May 2023, www.apqc.org/resource-library/resource-listing/inventory-optimization-show-me-money